User Tools

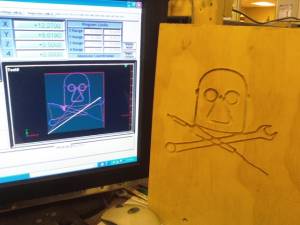

#38 CNC Router

Make/Model

Custom built by Ron Bean and Tom Gondek at Milwaukee Makerspace

Software

Mach3 controller software requires program in G-Code format

Use CamBam, Blender, EagleCAD, Inkscape, etc. to generate .DXF files

Then convert to .NGC or .NC format using ACE Converter or CamBam

Mach3 and CamBam are installed on the computer connected to the CNC Router.

The size of work area is: 24" x 32.5"

(1) Bosch 1617EVS router with 2-1/4 HP, 12 amp motor

Assembled In: Motor assembled in Mexico. Bases and other items made in China.

Base Diameter: 6“ Fixed/ 6-11/16” Plunge

Collet Capacity: 1/4“, 3/8”, 1/2“, 8mm

Cord Length: 10'

Max. Motor HP: 2.25

No Load RPM: 8,000 - 25,000

Used on Model No.: RA1171, RA1180, RA1181, RA1182, RA1200 Router Tables (Router in fixed base only).

Weight (lbs.): 19.5

(2) Oriental Motor Co. VEXTA C6244-9212K stepper motors (X,Y axes)

5.7V, 1.6A, 1.8 degrees/step, current limited - running 24v

(1) ALM 90130-25-SPA stepper motor (Z-axis)

5.7V, 1.6A, 1.8 degrees/step, current limited - running 24v

(2) Microtel SP-150-24IER power supplies

150 watt, 115vAC/1ph/60Hz 2.5 amp input, 24VDC 6.3 amp output

(1) Geckodrive G203V stepper motor driver

(2) Rorze Co. RD-023N stepper motor drivers

Bits

Ron Bean mentioned getting a 1/8” spiral upcut bit from these folks: http://www.woodline.com/p-1651-solid-carbide-spirals.aspx

Current Status

Disassembled and removed from space by Tom Gondek

Location

Not at space, removed by Tom Gondek

Previous: The Bodgery, Madison, WI

Previous: Wood Shop, West Room, Lenox

Previous: Workshop & Vehicle Bay, Chase

On lend from

History

01/15/11 - Work started

03/19/11 - First successful operation: MMS logo cut into a block of wood

Various improvements made throughout 2011

10/23/11 - First DIY CNC Day: Added E-stop buttons and relay-controlled spindle/vacuum power receptacles

11/27/11 - Disconnected the Z axis, maintenance

01/28/12 - Relocated from Workshop to Vehicle Bay

12/31/12 - Moved to Lenox

01/29/13 - Shower/Dust Curtain installed

Notes

Use 16 and 24mm collet wrenches

Manuals available for various parts

Videos available on Youtube

08/20/2011 - CNC Router Demo

08/20/2011 - How to change a bit in the router

10/23/2011 - First DIY CNC Day

11/18/2011 - Cutting Ornaments

Tips & Tricks .Doc available on the first post here

If you intend to cut a 3D Profile and are exporting an object from SketchUp, you'll need the STL exporter found here

Projects

Links to projects that used the CNC Router

- Stand for Automated Pet Food Dispenser