User Tools

This is an old revision of the document!

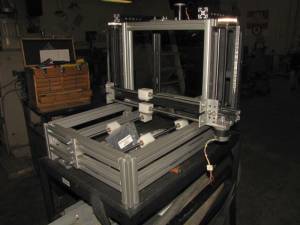

MegaMax 3D Printer

Plastic extrusion type 3D printer with approximately 1 cuft build envelope. My goal is to print life-sized human skulls from CT scan data. The machine uses 80/20 type aluminum extrusions for the frame and many scrounged parts generously supplied by the hack-rack, Tom G., and others at the makerspace. The design is loosely based on the MendelMax (Y-axis base, extruder on X-axis boom lifted by Z-axis screws), but I am sort of designing/cobbling as I go, one axis at a time, and fabricating parts as needed to fit the other pieces I have in-hand.

As of June 10th, this is what it looks like:

All three axes are nearly complete- just need to make the print platform for the Y-axis, and the print head(s)/extruder for the Z-axis. The X-axis is missing an idler pulley that will be added later this week. I have ordered a suitable belt and drive pulley for the Z-axis. With a little luck I'll be able to run some motion tests on the machine this weekend and see if my “precision” building practices have resulted in orthogonality of the axes and parallelism of the guide rails in each axis.

I have ordered a dual printhead from a KickStarter project that won't ship until August, so I'll start looking for another print head to use in the meantime.

Update: June 15th

I have fabricated the pulley for the far end of the X-axis, and the belt and drive pulley for the Z-axis screws arrived today. Looking forward to some simple motion tests this weekend. Working on the print platform design tonight…

Update June 17th:

The alignment technique for the guide rails worked as planned- I screwed an aluminum plate to the bushing blocks at the non-adjustable end of the guide rail, then slid the assembly to the other end and tightened the screws that hold the guide rails. Then I cut and mounted the belt and it seems like I get very smooth motion all the way across the x axis.

I also put the belt and drive pulley on the z axis and found that it too moves through the full range of motion without binding, and no adjustment was necessary.

I made a plate to mount on the Y-axis bushing blocks and found that the end pieces that hold the guide rails do not allow for easy adjustment of their positions. I'm going to redesign and fabricate the Y-axis guide rail end plates, possibly today.